Research & Development

Bearings Design & Calculation

Member of German Research Association for Combustion Engines FVV

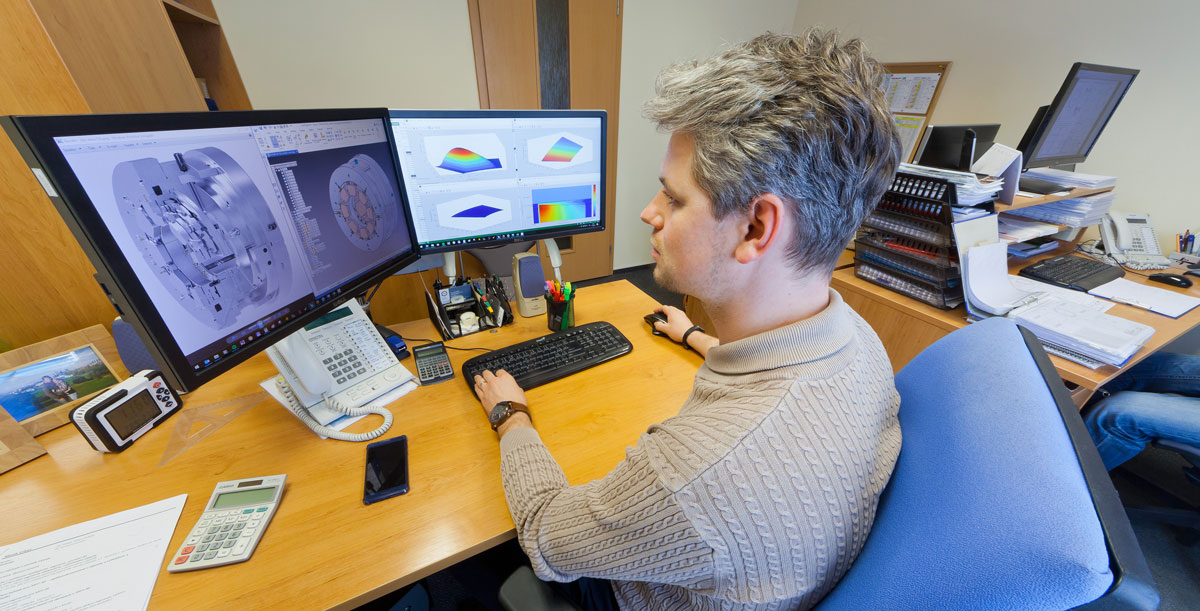

- our R&D department develops new products and follows through with the testing process at testing stations in the Czech Republic

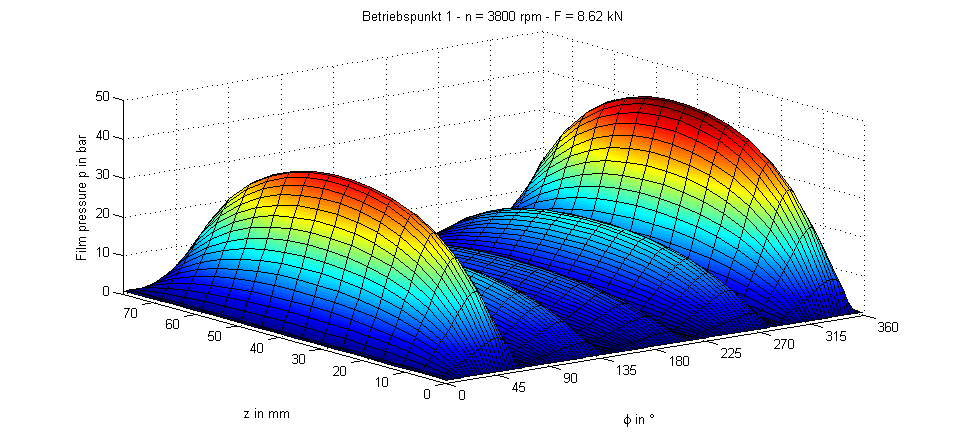

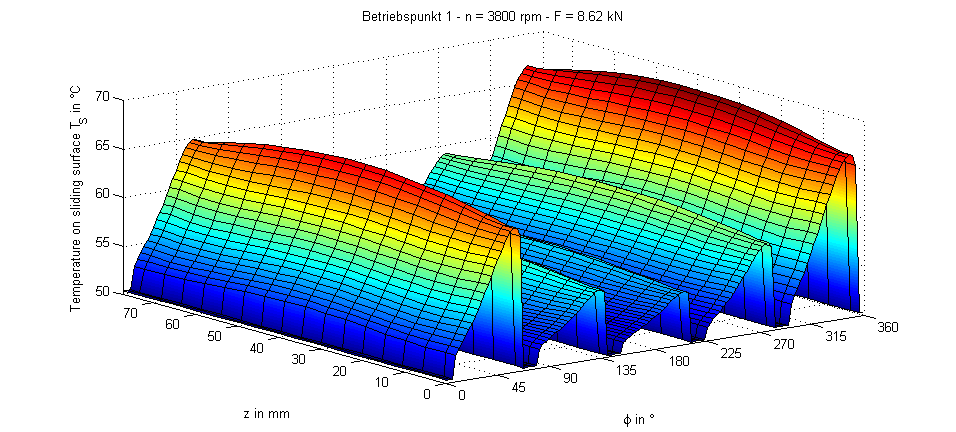

- our R&D department also custom-designs bearings for multiple types of machines, based on technical calculations

- outputs from technical calculations includes matrixes of stiffness and damping, power losses, determination of temperatures, minimal oil film thickness in a bearing and many others important factors

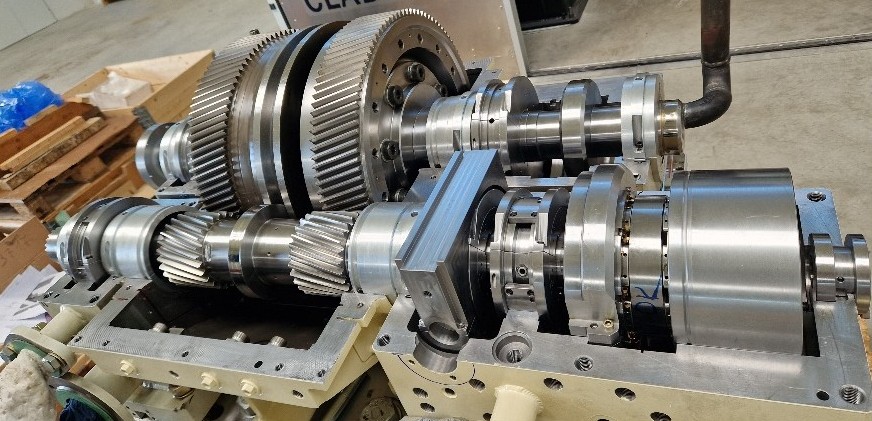

GTW Journal and Thrust Bearing Test Rig

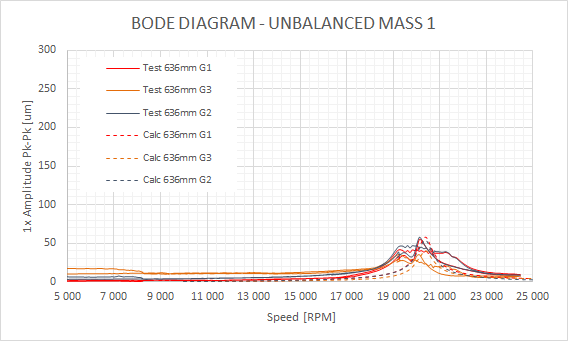

- we thoroughly test each of our new products before launch, both in terms of materials used and in-use behavior

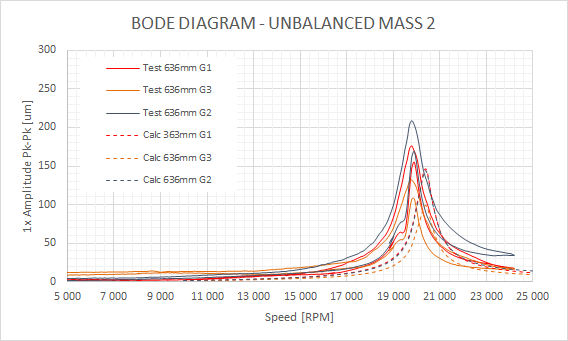

- we also test in order to refine the calculations precisely, allowing us the ability to compare the calculated values with the measured values

- measured values include: oil flow through each bearing separately; oil inlet and outlet temperatures; power loss; bearing temperature; eccentricity ratio; thrust load and vibration

JOURNAL BEARING TESTING

- the maximum speed on a low-speed shaft 10,000 rpm (pinion speed 40,380 rpm)

- pitch velocity 150 m/s

- maximum load 7 MPa ~ 25 kN

THRUST BEARING TESTING

- the maximum speed on a low-speed shaft 5,000 rpm (pinion speed 20,190 rpm)

- pitch velocity 120 m/s

- maximum load 5 MPa ~ 50 kN